What is Double Pipe Heat Exchanger Types. Working Principles Linquip

Calculations for Double-pipe Exchanger At Start Ecology's engineering design practice, we have sized several double-pipe heat exchangers, and below we share a step-by-step instruction for the design of these units. Commonly in these types of calculations, you have a known fluidic that is being cooled with heated.

SolidMechs Blog Types of Heat Exchangers

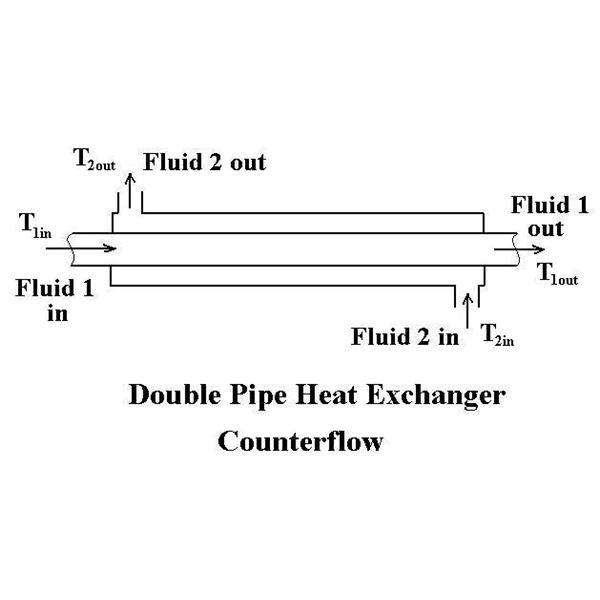

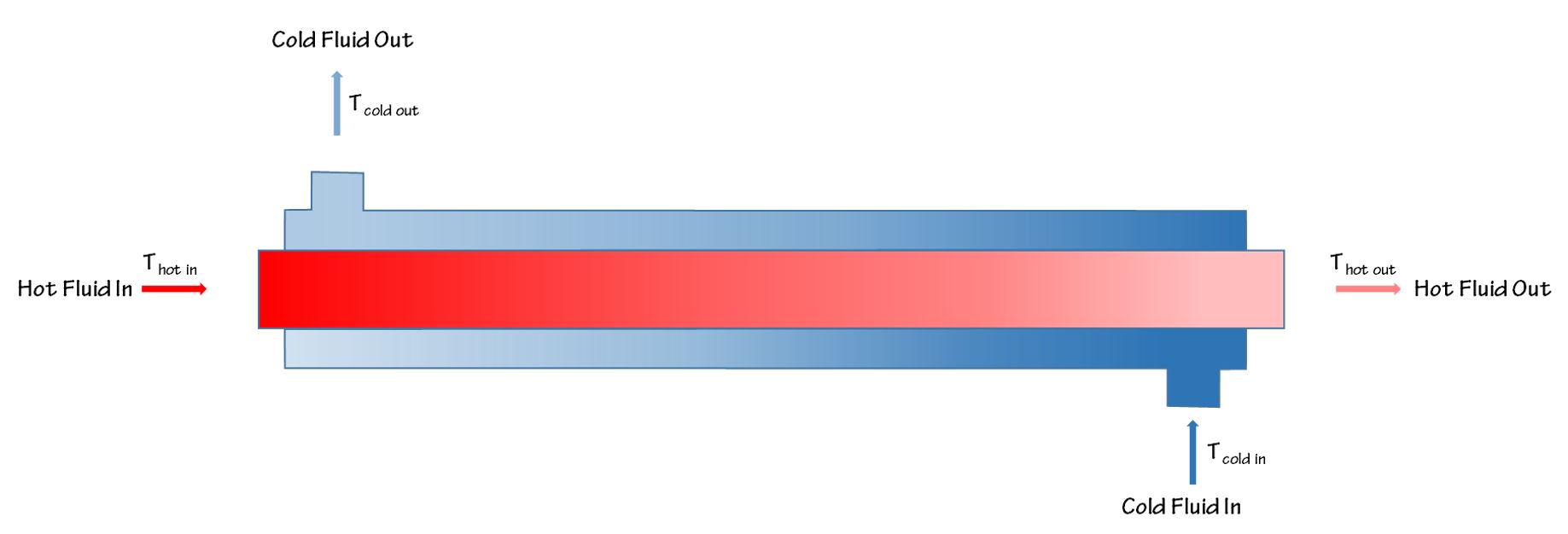

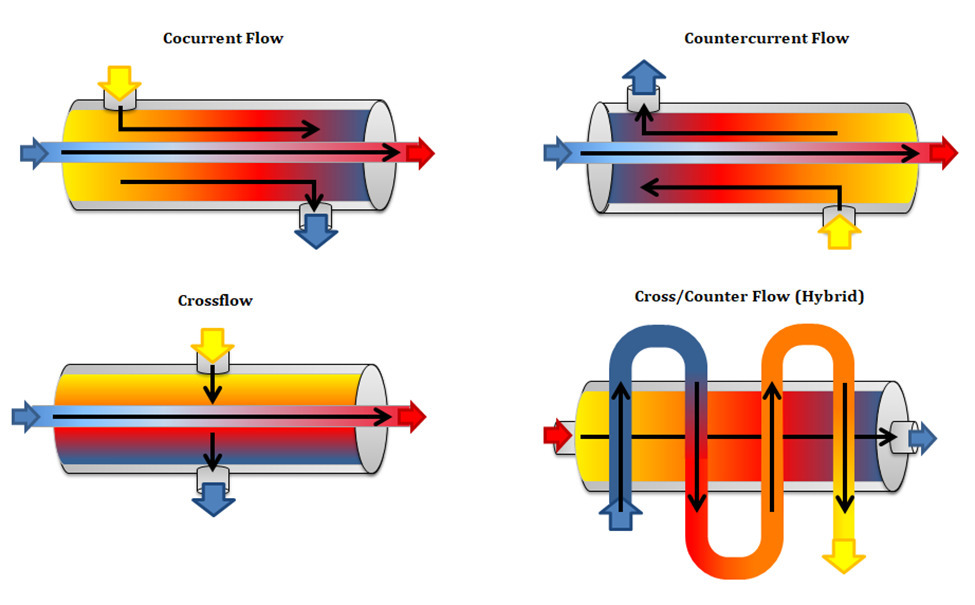

A double-pipe heat exchanger is the simplest type of heat exchanger and can operate with co-current (Figure 1) or counter-current (Figure 2) flow. The design consists of a single small pipe (tube-side) inside of a larger one (shell-side). A co-current heat exchanger is most commonly used when you want the exiting streams to leave the exchanger.

Doubletube heat exchanger Download Scientific Diagram

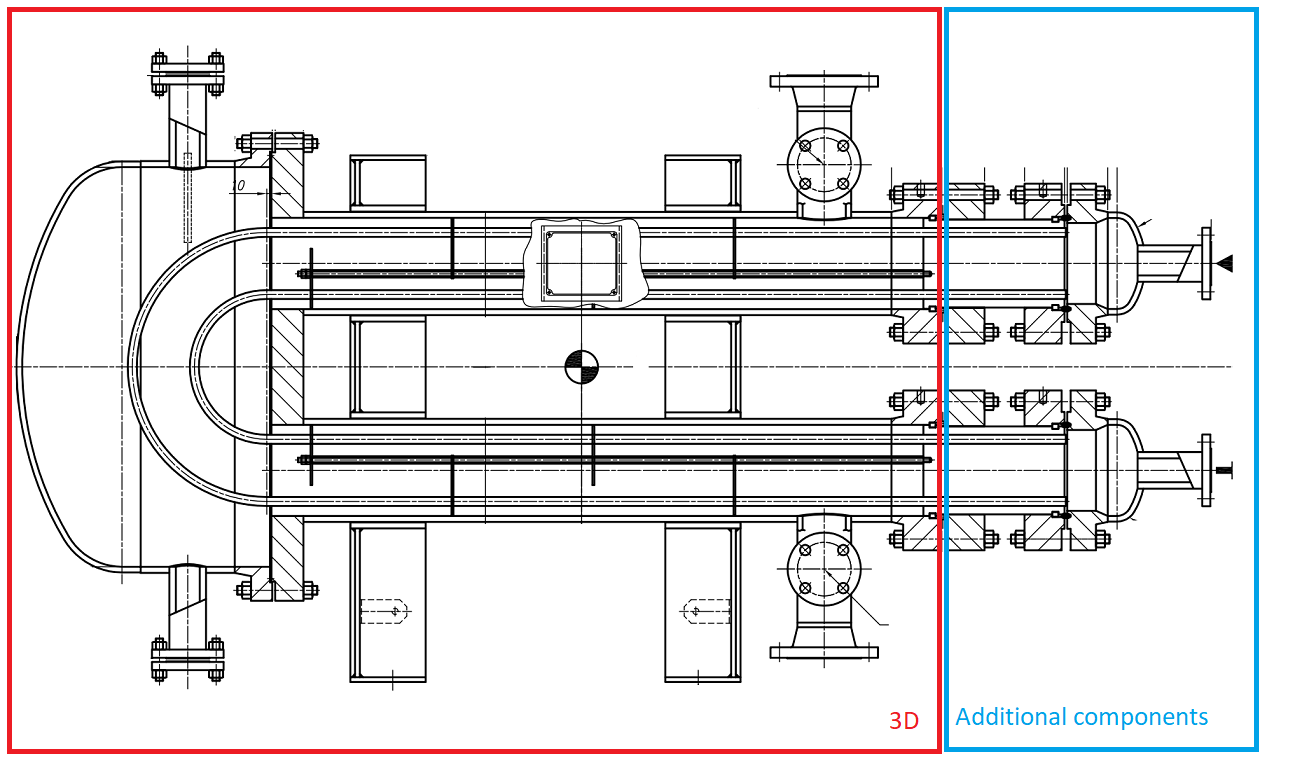

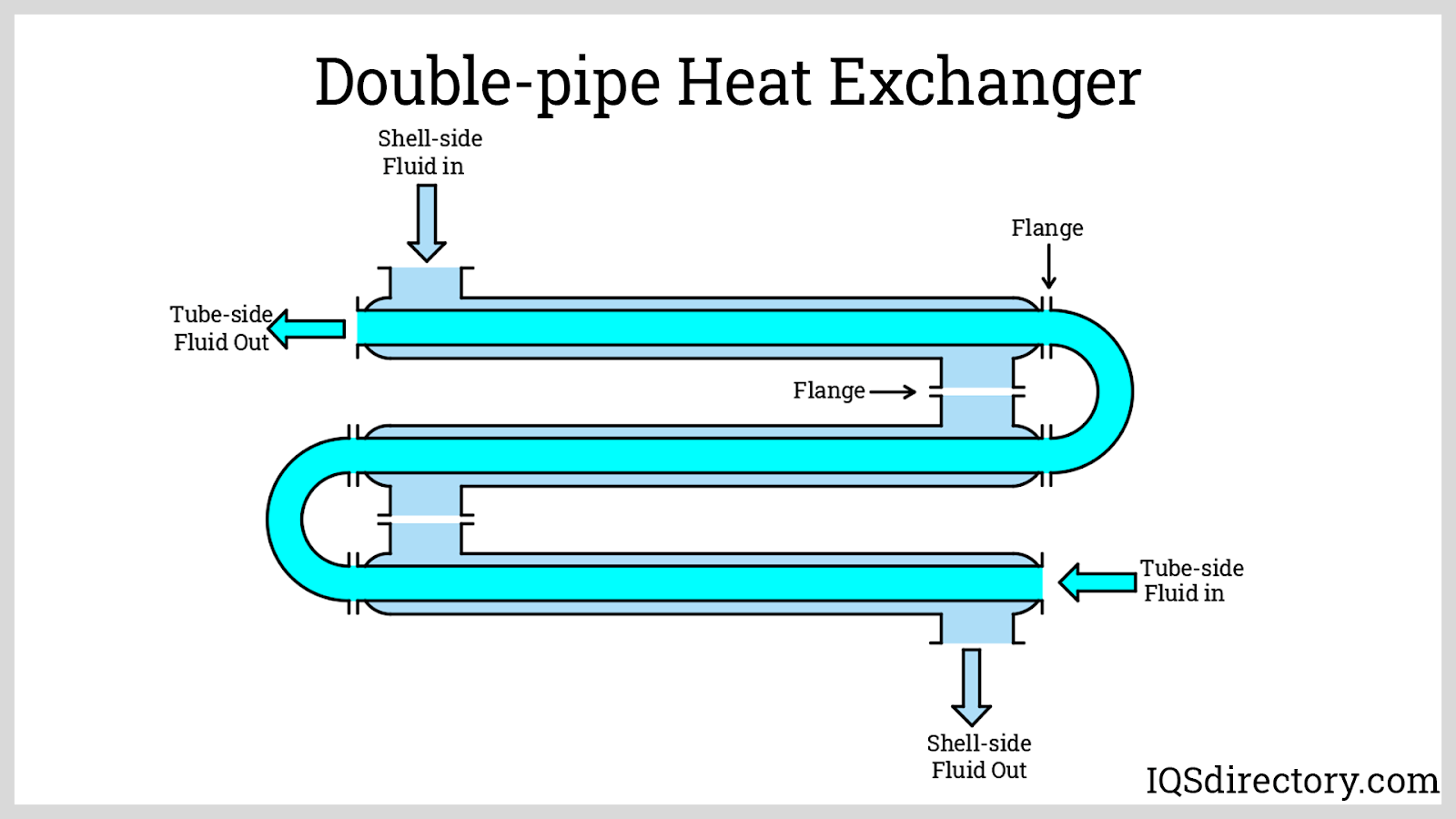

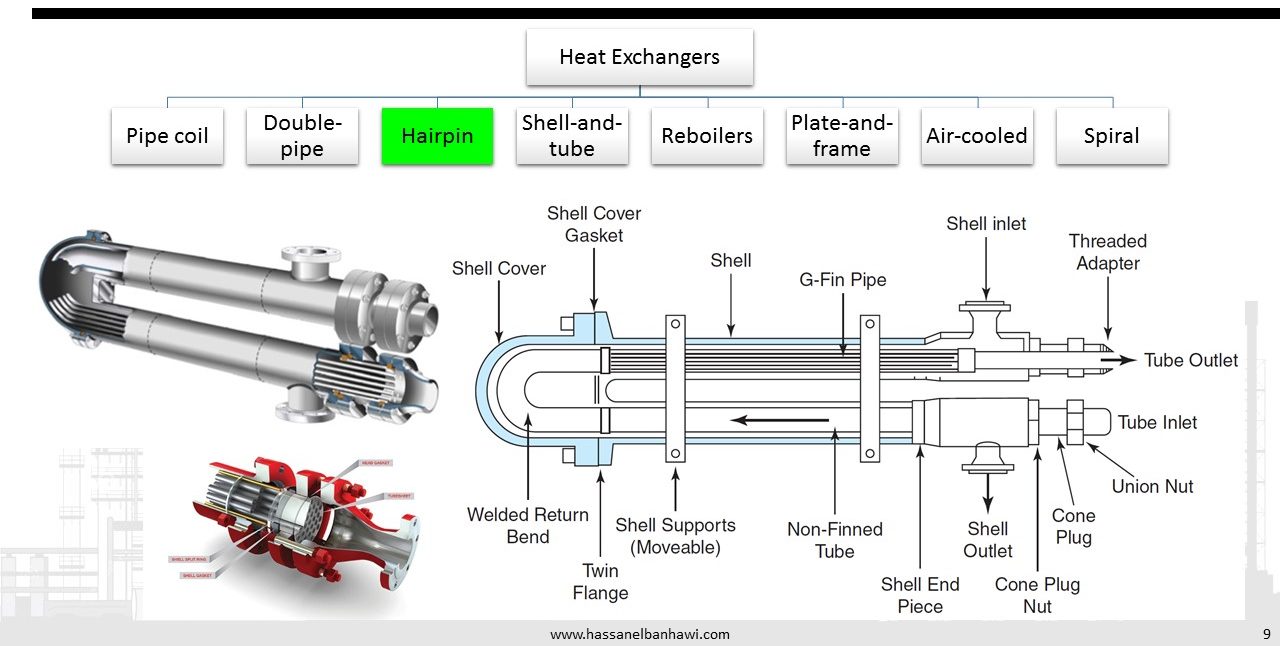

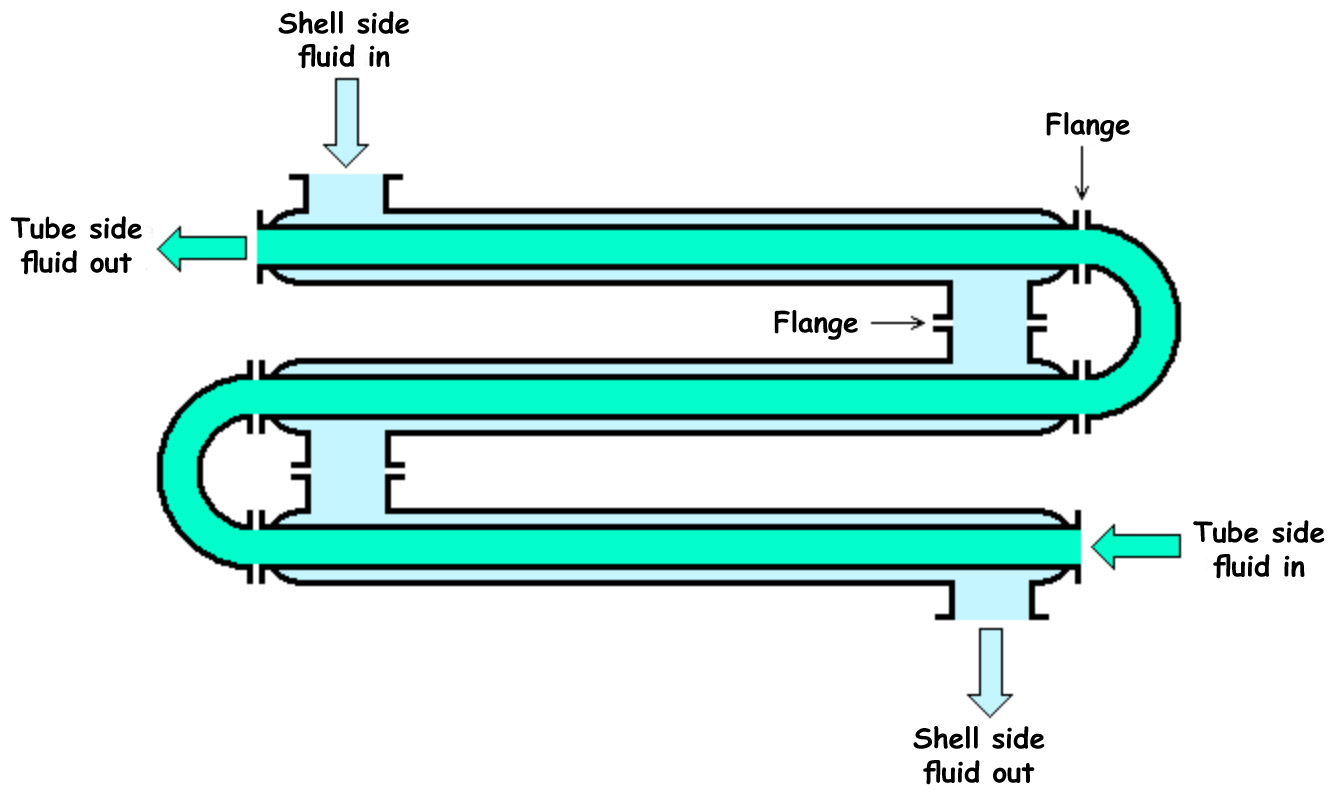

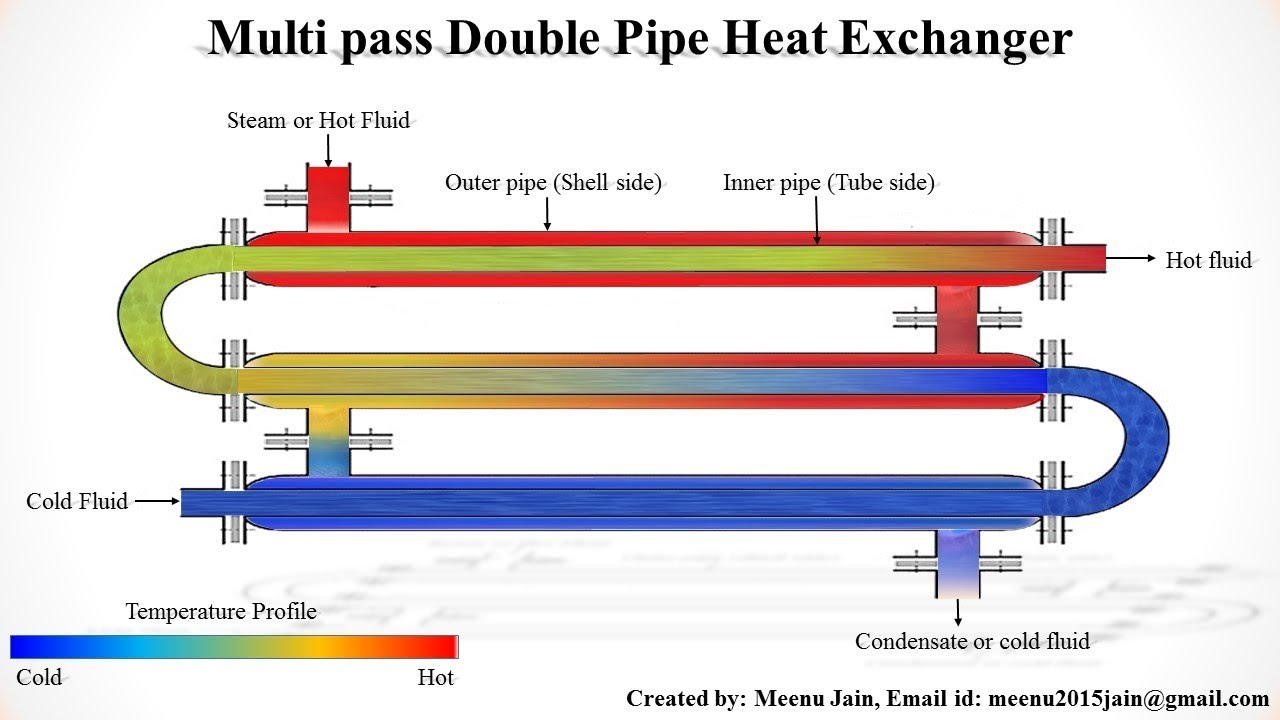

Figure 5 illustrates the spiral exchanger configuration. d) Double Pipe Exchanger. The Double Pipe exchanger is used when one liquid has a greater resistance to heat flow than another r when the surface area is small. As indicated in Figure 7, the double pipe exchanger consists of a pipe within a pipe ; both pipes have a return bend at one end.

How to Select the Right Heat Exchanger HVAC Global

Double pipe heat exchanger. Learn how a double pipe heat exchanger works with worked examples for tube in tube or double pipe heat exchangers as well as appl.

How to design an hairpin or double pipe heat exchanger Sant'Ambrogio NextGen Support

Download scientific diagram | Schematic drawing for the double pipe heat exchanger model from publication: Entropy Generation in Counter Flow Gas to Gas Heat Exchangers | Analysis of heat transfer.

Heat Exchanger Double Pipe Heat Exchanger

A double pipe exchanger is suited for "dirty" service because it is easy to dismantle and clean. In addition, a pipe exchanger can be considered in the following situations: 1. When the shell side coefficient is less than half that of the tube side; the annular side coefficient can be made comparable to the tube side. 2.

Double Pipe Heat Exchanger Pharmacy Scope

Double Pipe Heat Exchangers Layout. As shown below, the double pipe heat exchanger consists of a pipe within a pipe. Both pipes have a return bend at one end. Double Pipe Heat Exchanger Construction. The inner pipe is fitted with fins. The outer pipe acts as shell. The shell nozzles are mounted vertically from the outer pipe, and the tube.

3.3 Double Pipe Heat Exchanger

Kambiz Vafai. The present investigation proposes an innovative convergent double pipe heat exchanger (C-DPHE). A two-dimensional (2D) axisymmetric heat transfer model with counterflow is employed.

concentric tube heat exchanger lab report Jacob Fraser

A double pipe heat exchanger is a heat exchanger that uses two pipes to exchange heat between two fluids. One pipe has hot fluid while the other pipe has cold fluid. This heat exchanger is also called a jacketed U-tube, jacketed tube, hairpin, and pipe-in-pipe heat exchanger. They are most commonly used for transporting heat and air.

Process flow diagram for the doublepipe heat exchanger Download Scientific Diagram

Double Pipe Heat Exchangers- Heat exchangers are devices that transfer or exchange heat between two fluids without mixing and include various types depending on the design, application, required space, and the fluid flows in the system. All the heat exchangers have a barrier that separates the fluids and allows the heat transfer simultaneously.

Configuration of a double pipe heat exchanger. The inner pipe is the... Download Scientific

NTU. concentric tube or double pipe heat exchanger is one that is composed of two circular tubes. One fluid flows in the inner tube, while the other fluid flows in the annular space between the two tubes. In counterflow, the two fluids flow in parallel, but opposite directions.

freewallpaperforandroidtablet7inch

For first iteration a Length of double pipe exchanger is assumed and heat transfer coefficient is calculated. Viscosity correction factor (μ / μ w) 0.14 due to wall temperature is considered 1. For Laminar Flow (Re <= 2300), Seider Tate equation is used. Nu = 1.86 (Re.Pr.De/L )1/3(μ/ μw)0.14. For Transient & Turbulent Flow (Re > 2300.

Efficiency of Heat Exchanger Description and Formula Linquip

Calculations for Double-pipe Exchanger In Process Ecology's engineering design practice, we have sized several double-pipe heat exchangers, and below we share a step-by-step guide for the design of these units. Commonly in these types of calculations, you have a known fluid that is being cooled or heated.

Heat Exchangers Introduction Flow Arrangements and Types

scopes, the double-pipe heat exchanger can be stacked in series. Figure 1: Geometry and concept of the double-pipe heat exchanger. This tutorial shows how to efficiently model a double-pipe heat exchanger and focuses on preparing the geometry in order to build a suitable mesh manually. In addition, typical postprocessing options are shown.

Double pipe heat exchanger diagram,custom double pipe exchangerPrettech

A double pipe heat exchanger, in its simplest form is just one pipe inside another larger pipe. One fluid flows through the inside pipe and the other flows through the annulus between the two pipes. The wall of the inner pipe is the heat transfer surface.

Double Pipe Heat Exchanger Design Download and Install Windows

This study numerically investigates a double pipe heat exchanger with triangle and rectangle rib. The simulation is performed using ANSYS package, considering turbulent flow and k-e turbulence.